The remediation plan for Giant Mine includes a new water filtration plant to open in 2026 and the use of 800 thermosyphons to freeze arsenic trioxide chambers.

Natalie Plato, deputy director of the Giant Mine Remediation Project, gave a presentation at Yellowknife City Council yesterday about the new water treatment plant for the mine, scheduled to open next year. About 237,000 tonnes of arsenic trioxide is currently stored in the underground chambers at the site.

Plato says one of the main goals of the project is to prevent uncontrolled flooding of the mine, which could potentially release contaminants into the bay. The new system will pump water directly to the surface, pumping and treating the water, versus storing the water.

Council had invited the Giant Mined Remediation project leaders to council to talk about the mine and to talk about two “upset conditions,” one being a case scenario looking at what would happen if the water treatment plant fails for whatever reason, the mine water water level rises and we have contaminants releasing into the bay.

The second upset condition would be the case scenario of if the mine were to release effluent that is above target levels.

“What would happen in that scenario is we would stop discharging and then the mine water level would rise. So that would actually flip back to upset condition number one, so that’s the one I’ve brought out to really focus on today,” explained Plato.

The arsenic trioxide chambers are very close to the surface at Giant, about 100 to 200 feet below the surface.

For this reason, the water at Giant Mine is kept far below the Great Slave Lake water level, said Plato.

“So what that means is any water would kind of sort of go down to Giant, not out to Great Slave Lake in this current scenario where we keep the water level,” said Plato and explained that how Giant Mine manages water currently is how it has been managed for decades.

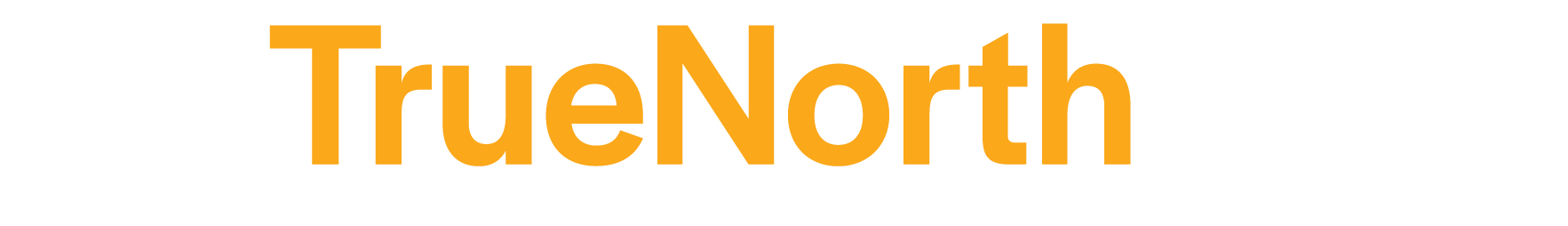

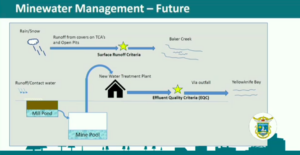

“We pump water from the underground up into the Northwest Pond.”

All water from the site is collected and stored there and then seasonally it gets pumped over to the ETP (the effluent treatment plant).

The water is stored in the Northwest Pond and runoff is also collected there, said Platto, which goes to the effluent treatment, plant settling and polishing ponds.

“We generally discharge seasonally, we store the water year-round and then usually starting July 1st, we pump, or we pump it over to the treatment plant, treat it and discharge it,” explained Plato.

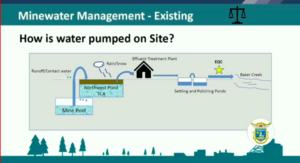

In just a little over a year, the new water treatment plant will take over that process with a different approach.

“We’re going to pump water directly from the underground through two wells directly to the surface and over to the water treatment plant, where it will be treated and it will be discharged through an outfall pipe,” said Plato

“The outfall pipe snakes around the old, we call it, the outfall road to the town site area and discharges directly into Yellowknife Back Bay. In an outfall submerged. So we’ll no longer be storing water. On the surface, we’ll be pumping continually and we’ll also be treating 365 days a year,” explained Plato.

After the water is treated, it will be discharged directly to Yellowknife Bay.

“And this new system will be into the foreseeable future. There is no end date for water treatment,” emphasized Plato.

Plato explained that one arsenic trioxide chamber was frozen about a decade ago to test it and they plan on freezing the remainder of the chambers with thermosyphons, which will be installed around all the chambers and function to extract the heat from the ground and freeze it.

Plato said the thermosyphons are basically tubes filled with carbon dioxide and they operate based on the ambient air temperature. When they’re cold, the gas turns to liquid.

“And it drops down, it can extract the heat by warming up and it just cycles around the thermocytes so they don’t require power,” she said.

“Once they’re installed, they’re pretty much zero maintenance,” added Plato, who emphasized that the Giant Mine Remediation project will be monitoring and maintaining them and there is also a planned future replacement of the over 800 thermosyphons.